IR® Technology

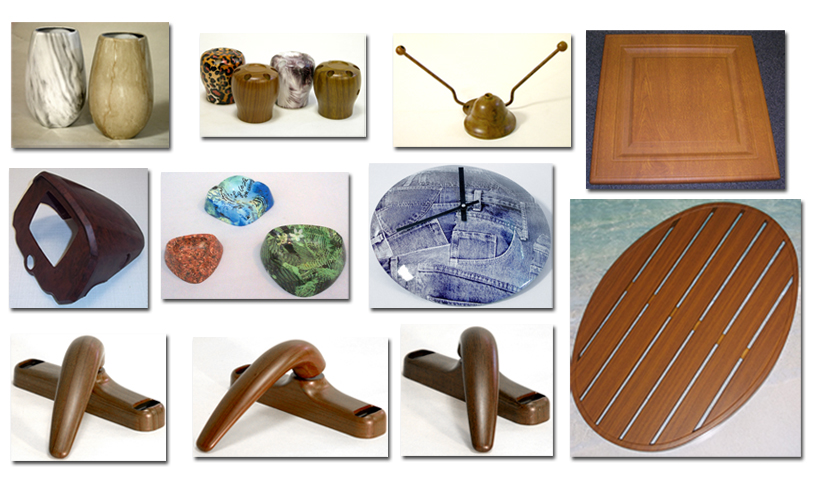

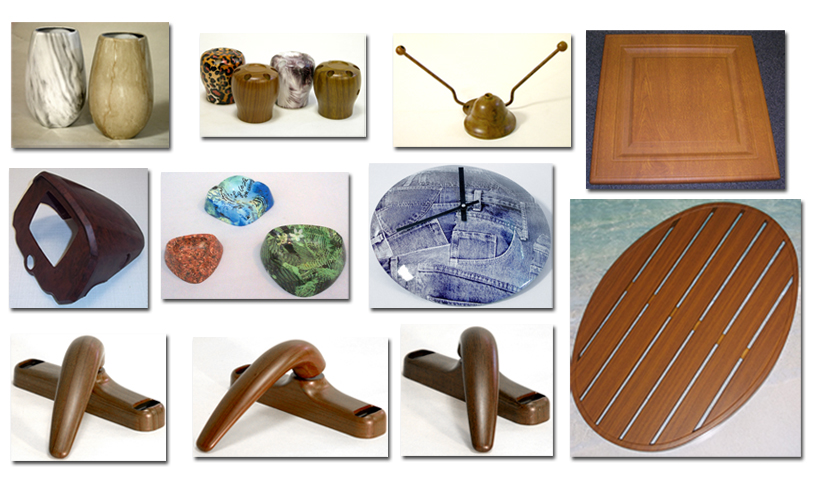

Decoral's IR® technology is specifically designed for the industrial and automatic decoration of 3D objects in high volume. Using Decoral's exclusive powder coat formulation with a unique combination of heat and pressure, almost any object/material may be decorated in a variety of finishes, such as wood grain, marble, or granite (door handles, knobs, shelves, welded parts, vases, faucets, wheels, etc). Additionally, custom logos or pictures can be applied to 3D objects as well.

MDF Decoration

IR® technology also permits the decoration of wood grain and other finishes into high temperature MDF boards that have been powder coated using Decoral powders. The IR® process is especially ideal for high volume MDF production of kitchen cabinets and raised or curved panels, such as furniture, shelving, toilet seats, etc.

With an unmatched ability and versatility to decorate 3-dimensional objects big or small, the possibilities are endless with Decoral's IR® technology.

IR® Machine models can decorate 3D parts up to 4' X 24'.

3D IR® Advantages

Does not peel or delaminate

More cost effective than lamination or veneer

High production capacity

No glues, no VOC, non fire hazard

Finish suitable for outdoor applications

Powder coating is environmentally safe

3D IR® Applications

Retail fixtures

Architectural

MDF Panels

Automotive

Welded parts

Furniture

Metal accessories

Almost any 3D objects